Decanter centrifuges pochotsa mapuloteni

Kufotokozera Kwachidule:

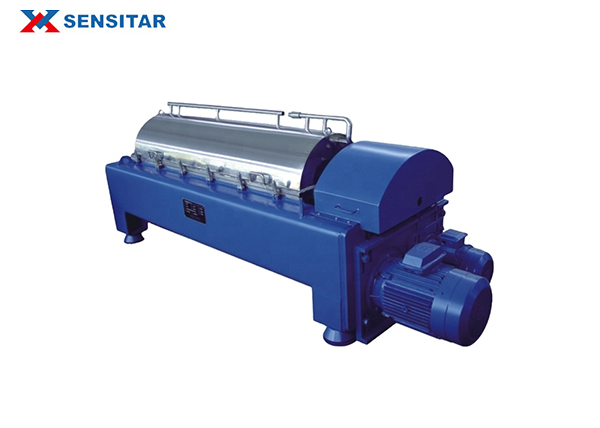

Makina opingasa amtundu wa spiral precipitated centrifugal amatchedwa makina opingasa amtundu wa spiral centrifugal mwachidule.Ndi chida champhamvu kwambiri chopingasa chamtundu wa spiral centrifugal potulutsa ndikulekanitsa ndi mvula.Nthawi zambiri, imatha kugawidwa m'makina opingasa amtundu wa spiral kusefa centrifugal ndi makina opingasa amtundu wa centrifugal.Amagwiritsidwa ntchito chifukwa madzi m'thupi kwa sludge mu zimbudzi mafakitale ndi m'nyumba, pambali, ndi ntchito i ...

Makina opingasa amtundu wa spiral precipitated centrifugal amatchedwa makina opingasa amtundu wa spiral centrifugal mwachidule.Ndi chida champhamvu kwambiri chopingasa chamtundu wa spiral centrifugal potulutsa ndikulekanitsa ndi mvula.

Nthawi zambiri, imatha kugawidwa m'makina opingasa amtundu wa spiral kusefa centrifugal ndi makina opingasa amtundu wa centrifugal.Amagwiritsidwa ntchito kwambiri chifukwa cha kuchepa kwa madzi m'thupi kwa sludge m'mafakitole ndi zimbudzi zapakhomo, komanso, amagwiritsidwanso ntchito m'mafakitale opanga mankhwala, ma pharmacy, chakudya ndi chitetezo cha chilengedwe, etc.

Ngakhale kuti barrate ndi spiral zimayenda mothamanga kwambiri komanso mozungulira ndi liwiro linalake, zinthu zimayambitsidwa ponyamula silinda yamkati mosalekeza kuchokera ku chitoliro cha chakudya, kenako kulowa mu barrate pambuyo pothamanga.

Gawo lolemera kwambiri lolimba limayika pakhoma la barrate ndikupanga wosanjikiza wa matope pansi pa gawo la centrifugal field.Kuyenda kozungulira kumakankhira gawo lolimba la sedimentary mpaka pa cone barrate mosalekeza, ndikutulutsa kuchokera pamakina kuchokera pakutsegula kwa slag-drip.

Chopepuka cholimba cholimba chimapanga mzere wozungulira wamadzimadzi, ndikusefukira kuchokera pachitseko chachikulu, kenako ndikutulutsa pamakina kuchokera pakulumikiza kukhetsa.Makinawa amatha kumaliza kudyetsa, kulekanitsa, kutsuka ndi kutulutsa mosalekeza akugwira ntchito mwachangu.

| Mtundu | Bowl awiri (mm) | Kutalika kwa mbale / Diameter ya mbale | Liwiro la mbale (r/min) | Main Power (Kw) |

| XLW180 | 180 | 2.5-720 | 6000 | 3-5.5 |

| XLW260 | 260 | 3.0-4 | 5000 | 7.5-11 |

| XLW355 | 355 | 2-4.5 | 4000 | 11-30 |

| XLW420 | 420 | 3-4.1 | 3600 | 18.5-37 |

| XLW450 | 450 | 2-4.4 | 3600 | 18.5-37 |

| XLW480 | 480 | 2-4.2 | 3200 | 18.5-45 |

| XLW500 | 500 | 2-4.2 | 3200 | 18.5-55 |

| XLW530 | 530 | 2-4 | 3200 | 22-55 |

| XLW580 | 580 | 2-4 | 2800 | 30-55 |

| XLW620 | 620 | 2-4 | 2800 | 37-110 |

| XLW760 | 760 | 2-3.5 | 2500 | 55-132 |

Kusinthasintha kwabwino: kuganiziridwa mozama zamitundu yonse yazinthu zapadera zomwe zimaperekedwa ndi zinthu ndi ukadaulo, kukhathamiritsa kwapangidwe kumakhazikitsidwa pazigawo zazikulu za kuyenerera ndi kusinthika.Malingana ngati ogwiritsa ntchito akufotokozera malo ake oyika, physicochemical properties of processing material and tochnological amafuna asanagule, tidzapereka chitsanzo choyenera kwambiri.

Madigiri apamwamba a automation:makinawa amamaliza kudyetsa, kulekanitsa, kutulutsa ndi zina zotero pamene akugwira ntchito ndi liwiro lapamwamba.Anazindikira kulamulira kwapadera kwa kupatukana kwa centrifugal ndi kutsuka kwa centrifugal pogwiritsa ntchito chowongolera chokhazikika.

Kukhazikika kogwira ntchito bwino: kusiyanitsa komwe kumagwiritsidwa ntchito ndi makinawa ndi kusiyanitsa kwa zida za cycloid kapena kusiyanitsa kwa zida zapadziko lapansi, kumakhala ndi torque yayikulu, kusintha kosiyanasiyana etc.

Kupanga kwabwino:kutengera makina amagetsi apawiri ndi kutembenuka kwapawiri pafupipafupi kutembenuka kwamphamvu kusinthika kosinthasintha kosinthasintha kuti aziwongolera, kusintha liwiro lozungulira mosinthika komanso mopanda malire ndikuwongolera liwiro lozungulira kwakanthawi malinga ndi kusintha kwa zinthu.Ndizogulitsa zenizeni zopulumutsa mphamvu.

Malo abwino ogwirira ntchito:makina a centrifugal amalekanitsa zinthu zotsekedwa kwathunthu.Izi zimaonetsetsa kuti malo ogwirira ntchito azikhala mwaukhondo komanso osadetsedwa, ndikuzindikira chitukuko cha chitukuko.

Chipangizo chachitetezo chokwanira komanso chodalirika:ili ndi chitetezo cha torque, kuwongolera mphamvu ndi zina, imatha kuthetsa kapena kuchepetsa kuwonongeka komwe kumachitika mwadzidzidzi.

Maonekedwe okopa:injini m'munsi kutengera apamwamba mpweya zitsulo kuti kuwotcherera, ndi pamwamba ndi yosalala pambuyo processing mwapadera.