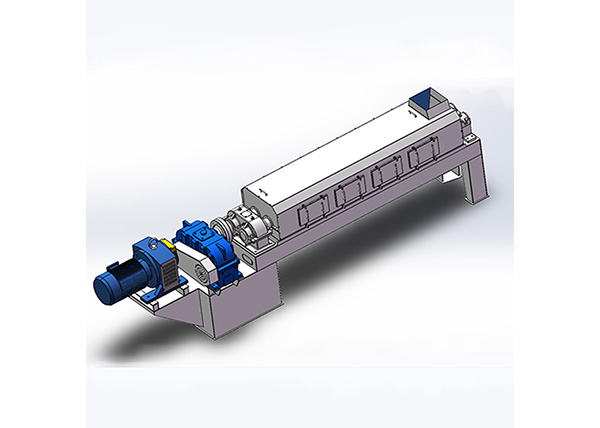

Wholesale Price China Shrimp Head Meal Dryer Machine / Shrimp and Fish Meal Making Machine

Short Description:

All we do is usually connected with our tenet ” Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for Wholesale Price China Shrimp Head Meal Dryer Machine / Shrimp and Fish Meal Making Machine, In case you are interested in almost any of our products and solutions, be sure to feel cost-free to contact us for additional aspects. We hope to cooperate with additional good friends from everywhere in the earth. All we do is usually connected wit...

All we do is usually connected with our tenet ” Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for Wholesale Price China Shrimp Head Meal Dryer Machine / Shrimp and Fish Meal Making Machine, In case you are interested in almost any of our products and solutions, be sure to feel cost-free to contact us for additional aspects. We hope to cooperate with additional good friends from everywhere in the earth.

All we do is usually connected with our tenet ” Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for China Fish Meal Machine and Rendering Plant, Welcome to visit our company, factory and our showroom where displays various products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

For pressing liquids from cooked fish or meat in a wet rendering process. The twin screw press ensures eficient mechanical dewatering and reduction of the oilfat content, which improves processing and increases the energy saving potential. The twin screw press attains a condition of high compression resulting ina low moisture and oilfat content in the press cake.

The press consists of two interlocking screws enclosed by a strainer shell and surrounded by a cover. The flights’ geometry can be cylindrical or biconical depending on the performance required and the type of material being processed. The screws rotate in opposite directions, preventing the material from rotating with the screws.

The strainer cage consists of perforated stainless steel plates surrounded by mild steel supporting plates, which are supported by heavy steel bridges.The strainer plate holes vary in size of the press from inlet to the outlet from 5 to 1. The twin screwpress can be dlivered as a conical or a cyindrica press One of the advantages of the conical type is that the flights of one screwreaches almostinto the core of the other screw.The result is minimum slip in the press and a more uniform press cake.

Twin-screw presses are often used to extract liquid from cooked fish or meat as part of low-temperature wet rendering processes.

They are also ideal as the first stage in mechanical dewatering processes, before the material enters a centrifugal decanter centrifuge.

They can also be used in high-capacity feather plants.

| Type | Capacity (t/h) |

Dimension(mm) | Weight (mt) |

Power (kW) |

||

| Length (L) | Width (W) | Height (H) | ||||

| TP 24 | 2.5 | 4400 | 1250 | 1030 | 3 | 7.5-11 |

| TP 35 | 5 | 5460 | 1800 | 1300 | 7 | 11-18.5 |

| MS 41 | 13 | 4600 | 2000 | 1500 | 9.5 | 22-37 |

| MS 49 | 18 | 5700 | 2400 | 1950 | 15.5 | 30-55 |

| MS 56 | 25 | 6700 | 2500 | 1870 | 23 | 45-75 |

| MS 64 | 40 | 7400 | 2800 | 2100 | 31 | 90-110 |

| RS64 | 50 | 8350 | 2800 | 2100 | 34 | 110-132 |

| XS88F | 60 | 8400 | 2850 | 2165 | 46 | 95-132 |