Supply ODM High Quality Shrimp Food Feed Meal Making Extruder Floating/ Sinking Fish Feed Pellet Production Machine

Short Description:

We will devote ourselves to supplying our esteemed prospects while using the most enthusiastically considerate providers for Supply ODM High Quality Shrimp Food Feed Meal Making Extruder Floating/ Sinking Fish Feed Pellet Production Machine, Our business is dedicated to giving customers with significant and secure top quality products at aggressive price, making each and every customer pleased with our services. We will devote ourselves to supplying our esteemed prospects while using the most...

We will devote ourselves to supplying our esteemed prospects while using the most enthusiastically considerate providers for Supply ODM High Quality Shrimp Food Feed Meal Making Extruder Floating/ Sinking Fish Feed Pellet Production Machine, Our business is dedicated to giving customers with significant and secure top quality products at aggressive price, making each and every customer pleased with our services.

We will devote ourselves to supplying our esteemed prospects while using the most enthusiastically considerate providers for China Shrimp Food Feed Machine and Shrimp Food Extruder, Our market share of our goods has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, make sure you feel free to contact us. We’ve been looking forward to forming successful business relationships with new clients around the world in the near future. We are looking forward to your inquiry and order.

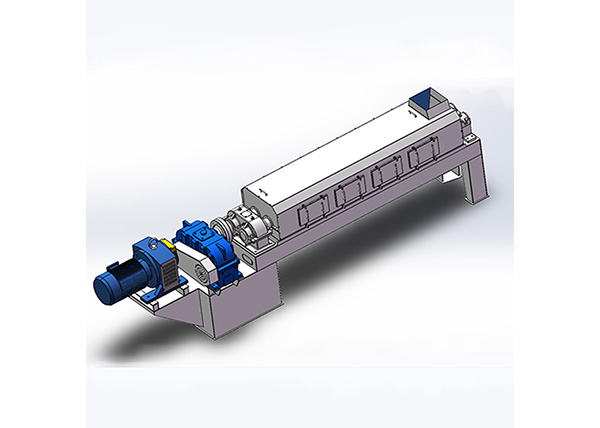

For pressing liquids from cooked fish or meat in a wet rendering process. The twin screw press ensures eficient mechanical dewatering and reduction of the oilfat content, which improves processing and increases the energy saving potential. The twin screw press attains a condition of high compression resulting ina low moisture and oilfat content in the press cake.

The press consists of two interlocking screws enclosed by a strainer shell and surrounded by a cover. The flights’ geometry can be cylindrical or biconical depending on the performance required and the type of material being processed. The screws rotate in opposite directions, preventing the material from rotating with the screws.

The strainer cage consists of perforated stainless steel plates surrounded by mild steel supporting plates, which are supported by heavy steel bridges.The strainer plate holes vary in size of the press from inlet to the outlet from 5 to 1. The twin screwpress can be dlivered as a conical or a cyindrica press One of the advantages of the conical type is that the flights of one screwreaches almostinto the core of the other screw.The result is minimum slip in the press and a more uniform press cake.

Twin-screw presses are often used to extract liquid from cooked fish or meat as part of low-temperature wet rendering processes.

They are also ideal as the first stage in mechanical dewatering processes, before the material enters a centrifugal decanter centrifuge.

They can also be used in high-capacity feather plants.

| Type | Capacity (t/h) |

Dimension(mm) | Weight (mt) |

Power (kW) |

||

| Length (L) | Width (W) | Height (H) | ||||

| TP 24 | 2.5 | 4400 | 1250 | 1030 | 3 | 7.5-11 |

| TP 35 | 5 | 5460 | 1800 | 1300 | 7 | 11-18.5 |

| MS 41 | 13 | 4600 | 2000 | 1500 | 9.5 | 22-37 |

| MS 49 | 18 | 5700 | 2400 | 1950 | 15.5 | 30-55 |

| MS 56 | 25 | 6700 | 2500 | 1870 | 23 | 45-75 |

| MS 64 | 40 | 7400 | 2800 | 2100 | 31 | 90-110 |

| RS64 | 50 | 8350 | 2800 | 2100 | 34 | 110-132 |

| XS88F | 60 | 8400 | 2850 | 2165 | 46 | 95-132 |