Special Design for High Efficiency Full- Automatic Meat and Bone Meal Making Machine Line

Short Description:

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for Special Design for High Efficiency Full- Automatic Meat and Bone Meal Making Machine Line, We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success! We can easily usually fulfill our respected customers with ...

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for Special Design for High Efficiency Full- Automatic Meat and Bone Meal Making Machine Line, We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for China Slaughter Waste Rendering Plant and Slaughter Waste Plant, With the goal of “zero defect”. To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Poultry Waste Meat Meal Rendering Plant Feed Processing Machine is suitable for poultry,poultry waste,pig,cow,sheep,fish,feather,bone,blood,all animal waste.High efficiency,all the machine can be equipped by customers requirement,a complete production line or a simple one just depend on all customers choice.

Finally product will be meal and oil,the meal can be used for poultry feed,the oil will be used for industrial oil.

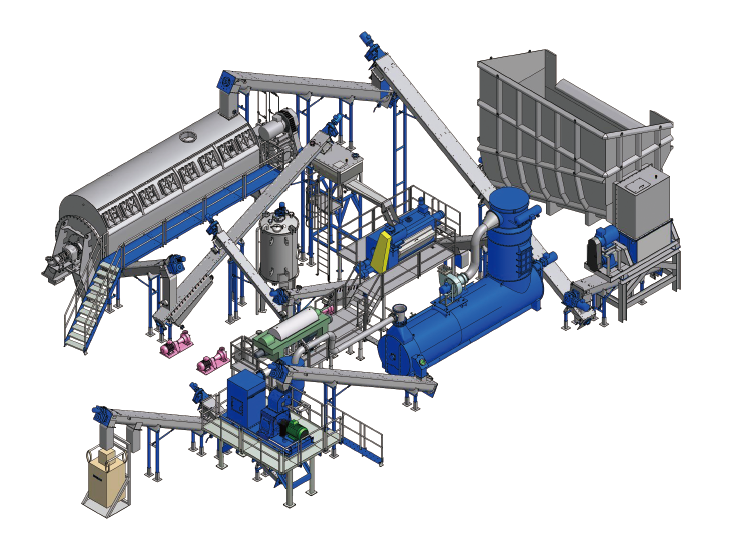

Raw Material Workflow

Pre-breaker System–Screw–Cook and Dry–Buffer–Press–Cooling–Mill–Automatic Packing

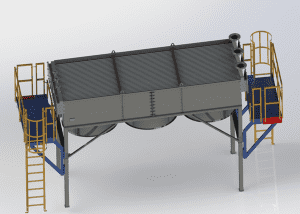

Waste Process Workflow

Waste Air Cooling–Spray and Washing–Flitter–High-energy Photon Oxidation–Discharge after reaching standard