Renewable Design for New Designed Automatic Chicken Meal Rendering Plant Machine-Feather Meal Hydrolyzer

Short Description:

Every single member from our higher effectiveness product sales staff values customers’ requires and organization communication for Renewable Design for New Designed Automatic Chicken Meal Rendering Plant Machine-Feather Meal Hydrolyzer, Top quality is factory’ existence , Focus on customer’ demand may be the source of enterprise survival and advancement, We adhere to honesty and good faith working attitude, seeking forward to the coming ! Every single member from our higher...

Every single member from our higher effectiveness product sales staff values customers’ requires and organization communication for Renewable Design for New Designed Automatic Chicken Meal Rendering Plant Machine-Feather Meal Hydrolyzer, Top quality is factory’ existence , Focus on customer’ demand may be the source of enterprise survival and advancement, We adhere to honesty and good faith working attitude, seeking forward to the coming !

Every single member from our higher effectiveness product sales staff values customers’ requires and organization communication for China Feather Meal Hydrolyzer and Hydrolyzer, All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our solutions are the best. Once Selected, Perfect Forever!

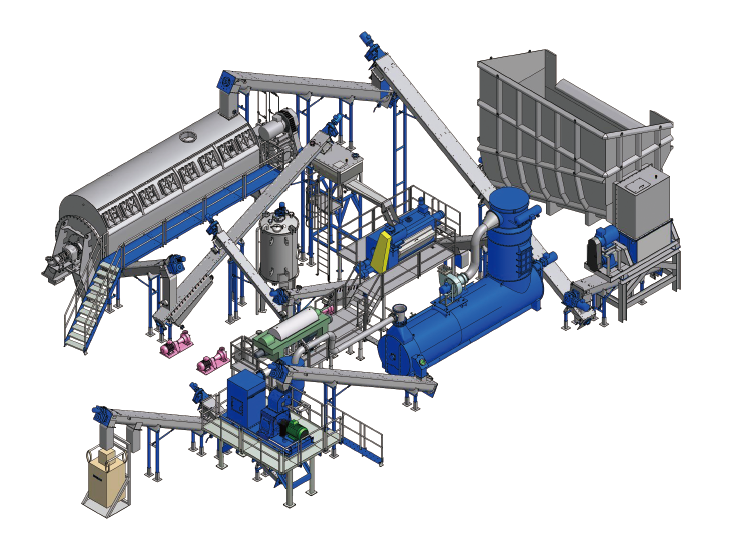

Poultry Waste Meat Meal Rendering Plant Feed Processing Machine is suitable for poultry,poultry waste,pig,cow,sheep,fish,feather,bone,blood,all animal waste.High efficiency,all the machine can be equipped by customers requirement,a complete production line or a simple one just depend on all customers choice.

Finally product will be meal and oil,the meal can be used for poultry feed,the oil will be used for industrial oil.

Raw Material Workflow

Pre-breaker System–Screw–Cook and Dry–Buffer–Press–Cooling–Mill–Automatic Packing

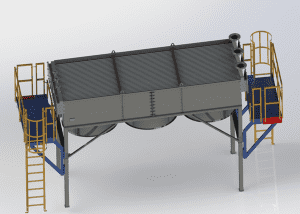

Waste Process Workflow

Waste Air Cooling–Spray and Washing–Flitter–High-energy Photon Oxidation–Discharge after reaching standard