One of Hottest for Meat and Bone Powder Rendering/Feather Powder Rendering

Short Description:

Sticking for the perception of “Creating products of top quality and producing friends with people today from all around the world”, we constantly place the desire of shoppers to start with for One of Hottest for Meat and Bone Powder Rendering/Feather Powder Rendering, Our concept is usually to aid presenting the confidence of each purchasers with the offering of our most honest provider, and the right product. Sticking for the perception of “Creating products of top quality...

Sticking for the perception of “Creating products of top quality and producing friends with people today from all around the world”, we constantly place the desire of shoppers to start with for One of Hottest for Meat and Bone Powder Rendering/Feather Powder Rendering, Our concept is usually to aid presenting the confidence of each purchasers with the offering of our most honest provider, and the right product.

Sticking for the perception of “Creating products of top quality and producing friends with people today from all around the world”, we constantly place the desire of shoppers to start with for China Meat and Bone Meal Processing Equipment and Animal Rendering Plant, We set a strict quality control system. We’ve return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our goods. Be sure to feel free to contact us for further information if you have any questions. We have been glad to work for every client.

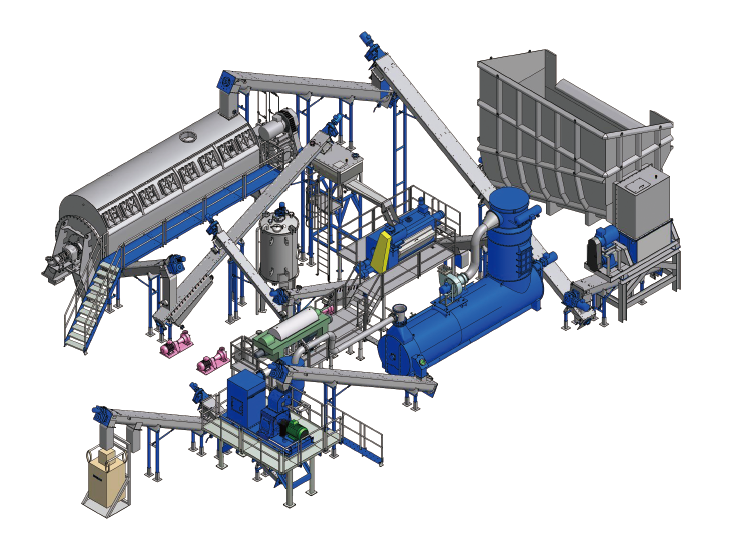

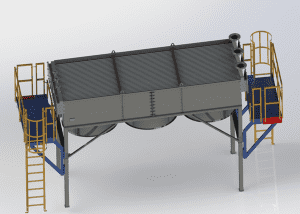

Poultry Waste Meat Meal Rendering Plant Feed Processing Machine is suitable for poultry,poultry waste,pig,cow,sheep,fish,feather,bone,blood,all animal waste.High efficiency,all the machine can be equipped by customers requirement,a complete production line or a simple one just depend on all customers choice.

Finally product will be meal and oil,the meal can be used for poultry feed,the oil will be used for industrial oil.

Raw Material Workflow

Pre-breaker System–Screw–Cook and Dry–Buffer–Press–Cooling–Mill–Automatic Packing

Waste Process Workflow

Waste Air Cooling–Spray and Washing–Flitter–High-energy Photon Oxidation–Discharge after reaching standard