One of Hottest for Automatic Poultry Waste Rendering Plant

Short Description:

“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for One of Hottest for Automatic Poultry Waste Rendering Plant, We’ve been keeping durable company relationships with far more than 200 wholesalers while in the USA, the UK, Germany and Canada. If you are fascinated in almost any of our products, be sure to come to feel ...

“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for One of Hottest for Automatic Poultry Waste Rendering Plant, We’ve been keeping durable company relationships with far more than 200 wholesalers while in the USA, the UK, Germany and Canada. If you are fascinated in almost any of our products, be sure to come to feel no cost to contact us.

“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for China Animal Rendering Plant and Animal Waste Rendering Plant, Our product quality is one of the major concerns and has been produced to meet the customer’s standards. “Customer services and relationship” is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

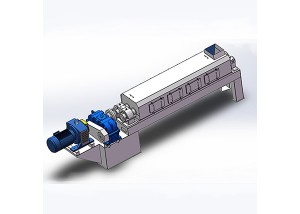

The quick water-flow type cooler will cool down the powder and granular material.When the material gets cool,this machine will select out different size products.

This robust, hard-wearing cooler enables you to use ambient air to cool a broad range of meal products (usually derived from poultry, fish or meat) after they have passed through a drying or cooking process. Cooling helps make the processed cake more brittle, so it’s easier to mill.

Rugged construction, few components and wearing parts makes this a reliable, inexpensive way to cool a wide range of meal products.

1.Fish meal Cooler adapt air cooling ,good cooling effect.

2.Fish meal Cooler use stainless steel pipe,corrosion resistance.

1.Fish meal Cooler is used to cool down the fish meal to room temperature.

2.The main part of the Fish meal Cooler is made of Q345 low alloy steel.

3.Stainless steel air blower.

4.Fish meal Cooler equipped with a air cooling conveyor after grinder.

1、Available in universal configuration or special hygienic design (for use in pet food processing, etc.)

2、Effective contact between cooling air and hot meal ensures best possible use of thermal inputs and energy consumption

3、Ensures cooling to safe storage temperatures

4、Few wearing parts and exceptional reliability

5、Savings on low installation, maintenance, manpower and operating costs