Oil Press/Pressing

Short Description:

①Introduction Twin Screw Press The twin screw press ensures eficient mechanical dewatering and reduction of the oilfat content,For pressing liquids from cooked fish or meat in a wet rendering process. which improves processing and increases the energy saving potential. The twin screw press attains a condition of high compression resulting ina low moisture and oilfat content in the press cake. The press consists of two interlocking screws enclosed by a strainer shell and surrounded by a cover....

①Introduction

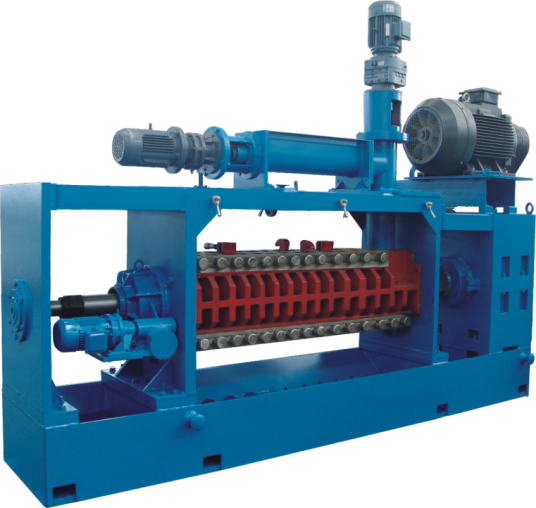

Twin Screw Press

The twin screw press ensures eficient mechanical dewatering and reduction of the oilfat content,For pressing liquids from cooked fish or meat in a wet rendering process. which improves processing and increases the energy saving potential. The twin screw press attains a condition of high compression resulting ina low moisture and oilfat content in the press cake.

The press consists of two interlocking screws enclosed by a strainer shell and surrounded by a cover. The flights’ geometry can be cylindrical or biconical depending on the performance required and the type of material being processed. The screws rotate in opposite directions, preventing the material from rotating with the screws.The strainer cage consists of perforated stainless steel plates surrounded by mild steel supporting plates, which are supported by heavy steel bridges.The strainer plate holes vary in size of the press from inlet to the outlet from 5 to 1. The twin screwpress can be dlivered as a conical or a cyindrica press One of the advantages of the conical type is that the flights of one screwreaches almostinto the core of the other screw.The result is minimum slip in the press and a more uniform press cake.

Application

Twin-screw presses are often used to extract liquid from cooked fish or meat as part of low-temperature wet rendering processes.

They are also ideal as the first stage in mechanical dewatering processes, before the material enters a centrifugal decanter centrifuge.

They can also be used in high-capacity feather plants.

BENEFITS

●High compression rate ensuresefficient continuous fat extraction

●Rugged and reliable equipment,with a long service life

●Low maintenance costs

②Introduction:

Oil Pressing

For continuous pressing of fat from cooked and dried animal and poultry by-products (often known as greaves).

Sensitar Oil Press provides highly effective mechanical extraction of th fat content from cooked and dried animal and poultry by-products, in a continuous flow. This enables you to achieve a hard cake with a low fat content. As the greaves pass along the single conical screw, the fat is pressed out into the surrounding enclosure, and the greaves are discharged as press cake. The fat runs into a collector trough, where a screw moves it to the outlet.

BENEFITS

1,With thick steel plate,more durable.

2,A variety of models,suitable for different processing capacity of customers.

3,Handing large quantities,occupy a small workshop area.

4,Small power consumption,easy to operation,management and maintenance.

5,Low residual oil press cake,good oil quality,the processed cake is loose and not fragile.