OEM/ODM Supplier Floating Fish Feed Pellet Making Machine Floating Fish Feed Machine Fish Feed Make Machine Floating Fish Feed Mill Pellet Extruder Machine

Short Description:

Using a total scientific good quality management process, superior high quality and excellent faith, we get great name and occupied this field for OEM/ODM Supplier Floating Fish Feed Pellet Making Machine Floating Fish Feed Machine Fish Feed Make Machine Floating Fish Feed Mill Pellet Extruder Machine, As a result of our hard perform, we have always been around the forefront of clean technology merchandise innovation. We’ve been a eco-friendly partner you can rely on. Get hold of us tod...

Using a total scientific good quality management process, superior high quality and excellent faith, we get great name and occupied this field for OEM/ODM Supplier Floating Fish Feed Pellet Making Machine Floating Fish Feed Machine Fish Feed Make Machine Floating Fish Feed Mill Pellet Extruder Machine, As a result of our hard perform, we have always been around the forefront of clean technology merchandise innovation. We’ve been a eco-friendly partner you can rely on. Get hold of us today for additional data!

Using a total scientific good quality management process, superior high quality and excellent faith, we get great name and occupied this field for China Fish Feed Pellet Machine and Feed Pellet Machine Line, Our company covers an area of 20, 000 square meters. We’ve got more than 200 workers, expert technical team, 15 years’ experience, exquisite workmanship, stable and reliable quality, competitive price and sufficient production capacity, this is how we make our customers stronger. If you have any inquiry, please do not hesitate to contact us.

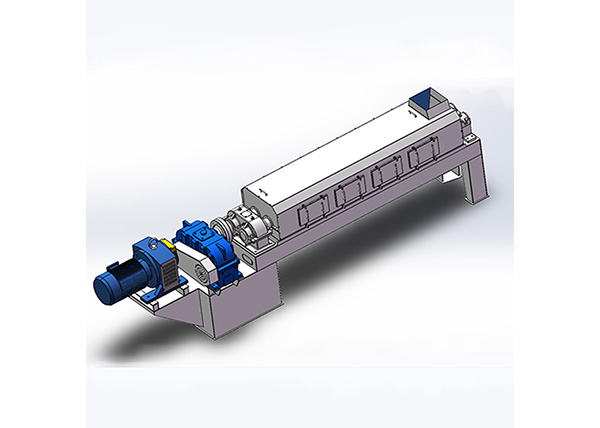

For pressing liquids from cooked fish or meat in a wet rendering process. The twin screw press ensures eficient mechanical dewatering and reduction of the oilfat content, which improves processing and increases the energy saving potential. The twin screw press attains a condition of high compression resulting ina low moisture and oilfat content in the press cake.

The press consists of two interlocking screws enclosed by a strainer shell and surrounded by a cover. The flights’ geometry can be cylindrical or biconical depending on the performance required and the type of material being processed. The screws rotate in opposite directions, preventing the material from rotating with the screws.

The strainer cage consists of perforated stainless steel plates surrounded by mild steel supporting plates, which are supported by heavy steel bridges.The strainer plate holes vary in size of the press from inlet to the outlet from 5 to 1. The twin screwpress can be dlivered as a conical or a cyindrica press One of the advantages of the conical type is that the flights of one screwreaches almostinto the core of the other screw.The result is minimum slip in the press and a more uniform press cake.

Twin-screw presses are often used to extract liquid from cooked fish or meat as part of low-temperature wet rendering processes.

They are also ideal as the first stage in mechanical dewatering processes, before the material enters a centrifugal decanter centrifuge.

They can also be used in high-capacity feather plants.

| Type | Capacity (t/h) |

Dimension(mm) | Weight (mt) |

Power (kW) |

||

| Length (L) | Width (W) | Height (H) | ||||

| TP 24 | 2.5 | 4400 | 1250 | 1030 | 3 | 7.5-11 |

| TP 35 | 5 | 5460 | 1800 | 1300 | 7 | 11-18.5 |

| MS 41 | 13 | 4600 | 2000 | 1500 | 9.5 | 22-37 |

| MS 49 | 18 | 5700 | 2400 | 1950 | 15.5 | 30-55 |

| MS 56 | 25 | 6700 | 2500 | 1870 | 23 | 45-75 |

| MS 64 | 40 | 7400 | 2800 | 2100 | 31 | 90-110 |

| RS64 | 50 | 8350 | 2800 | 2100 | 34 | 110-132 |

| XS88F | 60 | 8400 | 2850 | 2165 | 46 | 95-132 |