OEM/ODM Factory Poultry and Waste Rendering Plant Manufacturers/China Feather Meal Plant Manufacturers

Short Description:

We stay with the basic principle of “quality initially, services first, steady improvement and innovation to fulfill the customers” for your management and “zero defect, zero complaints” as the quality objective. To perfect our company, we give the goods while using the good high-quality at the reasonable selling price for OEM/ODM Factory Poultry and Waste Rendering Plant Manufacturers/China Feather Meal Plant Manufacturers, Thanks for taking your worthwhile time to vi...

We stay with the basic principle of “quality initially, services first, steady improvement and innovation to fulfill the customers” for your management and “zero defect, zero complaints” as the quality objective. To perfect our company, we give the goods while using the good high-quality at the reasonable selling price for OEM/ODM Factory Poultry and Waste Rendering Plant Manufacturers/China Feather Meal Plant Manufacturers, Thanks for taking your worthwhile time to visit us and sit up for have a nice cooperation along with you.

We stay with the basic principle of “quality initially, services first, steady improvement and innovation to fulfill the customers” for your management and “zero defect, zero complaints” as the quality objective. To perfect our company, we give the goods while using the good high-quality at the reasonable selling price for China Bone Meal Machine and Bone Meal Plant, To keep the leading position in our industry, we never stop challenging the limitation in all aspects to create the ideal products. In his way, We can enrich our life style and promote a better living environment for the global community.

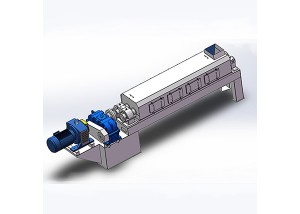

The quick water-flow type cooler will cool down the powder and granular material.When the material gets cool,this machine will select out different size products.

This robust, hard-wearing cooler enables you to use ambient air to cool a broad range of meal products (usually derived from poultry, fish or meat) after they have passed through a drying or cooking process. Cooling helps make the processed cake more brittle, so it’s easier to mill.

Rugged construction, few components and wearing parts makes this a reliable, inexpensive way to cool a wide range of meal products.

1.Fish meal Cooler adapt air cooling ,good cooling effect.

2.Fish meal Cooler use stainless steel pipe,corrosion resistance.

1.Fish meal Cooler is used to cool down the fish meal to room temperature.

2.The main part of the Fish meal Cooler is made of Q345 low alloy steel.

3.Stainless steel air blower.

4.Fish meal Cooler equipped with a air cooling conveyor after grinder.

1、Available in universal configuration or special hygienic design (for use in pet food processing, etc.)

2、Effective contact between cooling air and hot meal ensures best possible use of thermal inputs and energy consumption

3、Ensures cooling to safe storage temperatures

4、Few wearing parts and exceptional reliability

5、Savings on low installation, maintenance, manpower and operating costs