New Arrival China Full Automatic Pet Dog Cat Food Fish Float Aquatic Feed Processing Production Line Making Machine

Short Description:

We stick to our enterprise spirit of “Quality, Performance, Innovation and Integrity”. We purpose to create a lot more price for our prospects with our rich resources, innovative machinery, experienced workers and great products and services for New Arrival China Full Automatic Pet Dog Cat Food Fish Float Aquatic Feed Processing Production Line Making Machine, Our concept is usually to aid presenting the confidence of each purchasers with the offering of our most honest provider, ...

We stick to our enterprise spirit of “Quality, Performance, Innovation and Integrity”. We purpose to create a lot more price for our prospects with our rich resources, innovative machinery, experienced workers and great products and services for New Arrival China Full Automatic Pet Dog Cat Food Fish Float Aquatic Feed Processing Production Line Making Machine, Our concept is usually to aid presenting the confidence of each purchasers with the offering of our most honest provider, and the right product.

We stick to our enterprise spirit of “Quality, Performance, Innovation and Integrity”. We purpose to create a lot more price for our prospects with our rich resources, innovative machinery, experienced workers and great products and services for China Pet Food Making Machine and Fish Feed Making Machine, With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the “quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

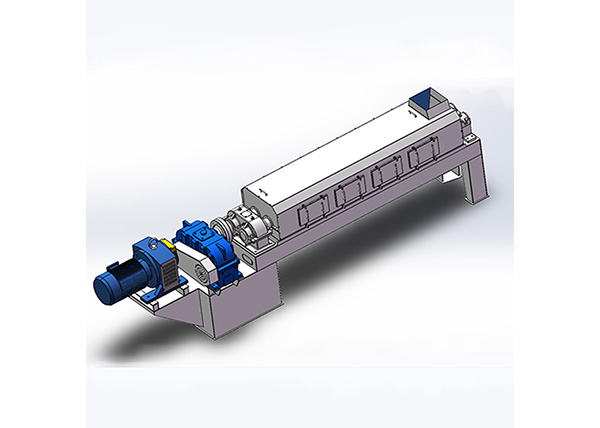

For pressing liquids from cooked fish or meat in a wet rendering process. The twin screw press ensures eficient mechanical dewatering and reduction of the oilfat content, which improves processing and increases the energy saving potential. The twin screw press attains a condition of high compression resulting ina low moisture and oilfat content in the press cake.

The press consists of two interlocking screws enclosed by a strainer shell and surrounded by a cover. The flights’ geometry can be cylindrical or biconical depending on the performance required and the type of material being processed. The screws rotate in opposite directions, preventing the material from rotating with the screws.

The strainer cage consists of perforated stainless steel plates surrounded by mild steel supporting plates, which are supported by heavy steel bridges.The strainer plate holes vary in size of the press from inlet to the outlet from 5 to 1. The twin screwpress can be dlivered as a conical or a cyindrica press One of the advantages of the conical type is that the flights of one screwreaches almostinto the core of the other screw.The result is minimum slip in the press and a more uniform press cake.

Twin-screw presses are often used to extract liquid from cooked fish or meat as part of low-temperature wet rendering processes.

They are also ideal as the first stage in mechanical dewatering processes, before the material enters a centrifugal decanter centrifuge.

They can also be used in high-capacity feather plants.

| Type | Capacity (t/h) |

Dimension(mm) | Weight (mt) |

Power (kW) |

||

| Length (L) | Width (W) | Height (H) | ||||

| TP 24 | 2.5 | 4400 | 1250 | 1030 | 3 | 7.5-11 |

| TP 35 | 5 | 5460 | 1800 | 1300 | 7 | 11-18.5 |

| MS 41 | 13 | 4600 | 2000 | 1500 | 9.5 | 22-37 |

| MS 49 | 18 | 5700 | 2400 | 1950 | 15.5 | 30-55 |

| MS 56 | 25 | 6700 | 2500 | 1870 | 23 | 45-75 |

| MS 64 | 40 | 7400 | 2800 | 2100 | 31 | 90-110 |

| RS64 | 50 | 8350 | 2800 | 2100 | 34 | 110-132 |

| XS88F | 60 | 8400 | 2850 | 2165 | 46 | 95-132 |