Manufacturer for China Chicken Feed Production Line Rendering Plant

Short Description:

We aim to find out high quality disfigurement in the generation and provide the most effective services to domestic and abroad clients wholeheartedly for Manufacturer for China Chicken Feed Production Line Rendering Plant, Our intention is “blazing new floor, Passing Value”, inside the long term, we sincerely invite you to increase up with us and generate a vibrant long term together! We aim to find out high quality disfigurement in the generation and provide the most effective se...

We aim to find out high quality disfigurement in the generation and provide the most effective services to domestic and abroad clients wholeheartedly for Manufacturer for China Chicken Feed Production Line Rendering Plant, Our intention is “blazing new floor, Passing Value”, inside the long term, we sincerely invite you to increase up with us and generate a vibrant long term together!

We aim to find out high quality disfigurement in the generation and provide the most effective services to domestic and abroad clients wholeheartedly for China Slaughter Waste Rendering Plant, Slaughter Waste Plant, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our goods. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you personally always.

Introduction

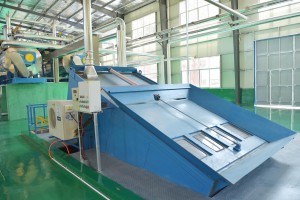

Indirectly steam-heated and designed for continuous cooking or drying of animal by-products or fish.The rotor consists of a central pipe on which vertically arranged and parallel discs with double walls have been welded.This design results in a concentrated heating surface offering maximum evaporation capacity in a compact design.

The wet material is fed into the dryer through the inlet at the drive end.The material is transported through the dryer and agitated by means of paddles mounted on the periphery of the rotor.

The material is dried by direct contact with the steam-heated surface of the rotor.The water evaporated from the material is removed through the vapour dome at the top of the stator.

The steam inlet is at the non -drive end of the rotor,and the condensate outlet is placed at the drive end.Scraper bars are designed to prevent material buil-up between the discs of the rotor.

The dried material is discharged at the opposite end at the bottom of the stator typically through a discharge screw conveyor with variable speed drive.

Main Character

The stator incl.vapour dome,inlet and outlets as well as the scraper bars between the discs and the adjustable paddles are manufactured in stainless steel.

The vapour dome has removable covers for easy inspection,cleaning and adjustment of the paddles.Every second cover is equipped with an inspection glass with light and wiper for easy inspection.

The disc dryer has oil lubricated external bearings.

The shafts to the dryer are sealed with stuffing boxes.

Technical Specifications

|

Dryer type |

Heating surface |

Power |

Shipping data |

|||

|

|

㎡ |

KW |

Length |

Width |

Height |

Weight |

|

mm |

mm |

mm |

ton |

|||

|

1228 |

60 |

30 |

7750 |

2050 |

2600 |

22 |

|

1242 |

90 |

45 |

9700 |

2050 |

2600 |

26 |

|

1537 |

110 |

45 |

9050 |

2200 |

3200 |

30 |

|

1542 |

130 |

45 |

9750 |

2200 |

3200 |

31 |

|

1551 |

150 |

55 |

11100 |

2200 |

3200 |

37 |

|

1850 |

215 |

75 |

11100 |

2560 |

3500 |

52 |

|

2050 |

260 |

75 |

11300 |

2800 |

3650 |

59 |

|

2064 |

320 |

90 |

13250 |

2800 |

3650 |

68 |

|

2264 |

375 |

110 |

14000 |

3000 |

3850 |

79 |

|

2550 |

400 |

110 |

12200 |

3300 |

4150 |

84 |

|

2564 |

515 |

132 |

14150 |

3300 |

4150 |

99 |

|

2578 |

595 |

160 |

16150 |

3300 |

4150 |

120 |

|

2864 |

650 |

160 |

14150 |

3600 |

4500 |

116 |

|

2878 |

730 |

200 |

16150 |

3600 |

4500 |

135 |

ABOUT US

Shandong Sensitar Machinery Manufacturing Co.Ltd. is a famous supplier of animal waste protein handling processboth at home and abroad.Our company owned authorized pressure vessel certificate(Certificate No.TS2237474-2016);CE certificate,ASME certificate.Our company majored in dead animal harmless handle and recy-cle.Our technical is at a leading level in the professional organic waste recycle and reuse business.Gathering theadvanced biological technology,we created the advanced dead animal harmless comprehensive handling equip-ment.The process line machine we designed has a lot of superior characters including high automation,definite safety,low labor intensity and etc.lt achieves a high standard goal of simple,continuous and efficient manufacture technology.

Sensitar owns a large amount superb skilled staff.Our professional engineer will design a professional process fordifferent condition.At the same time,we will provide a superior after-service at the goal-Service to the first,quality tothe success.

In recent years,our company cooperated with many outstand companies both at home and abroad.

EXHIBITION

CUSTOMER SITE

CERTIFICATIONS

CONTACT US