Hot-selling Manufacturing Companies for High Efficiency Abattoir Waste Batch Cooker/Rendering Plant

Short Description:

carry on to boost, to guarantee products excellent in line with market and consumer standard specifications. Our enterprise has a quality assurance system are actually established for Hot-selling Manufacturing Companies for High Efficiency Abattoir Waste Batch Cooker/Rendering Plant, We sincerely welcome mates from all over the globe to cooperate with us to the basis of long-term mutual added benefits. carry on to boost, to guarantee products excellent in line with market and consumer standar...

carry on to boost, to guarantee products excellent in line with market and consumer standard specifications. Our enterprise has a quality assurance system are actually established for Hot-selling Manufacturing Companies for High Efficiency Abattoir Waste Batch Cooker/Rendering Plant, We sincerely welcome mates from all over the globe to cooperate with us to the basis of long-term mutual added benefits.

carry on to boost, to guarantee products excellent in line with market and consumer standard specifications. Our enterprise has a quality assurance system are actually established for China Animal Waste Rendering Plant and Rendering Plant for Dead Animal, With the advanced workshop, professional design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our products are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.

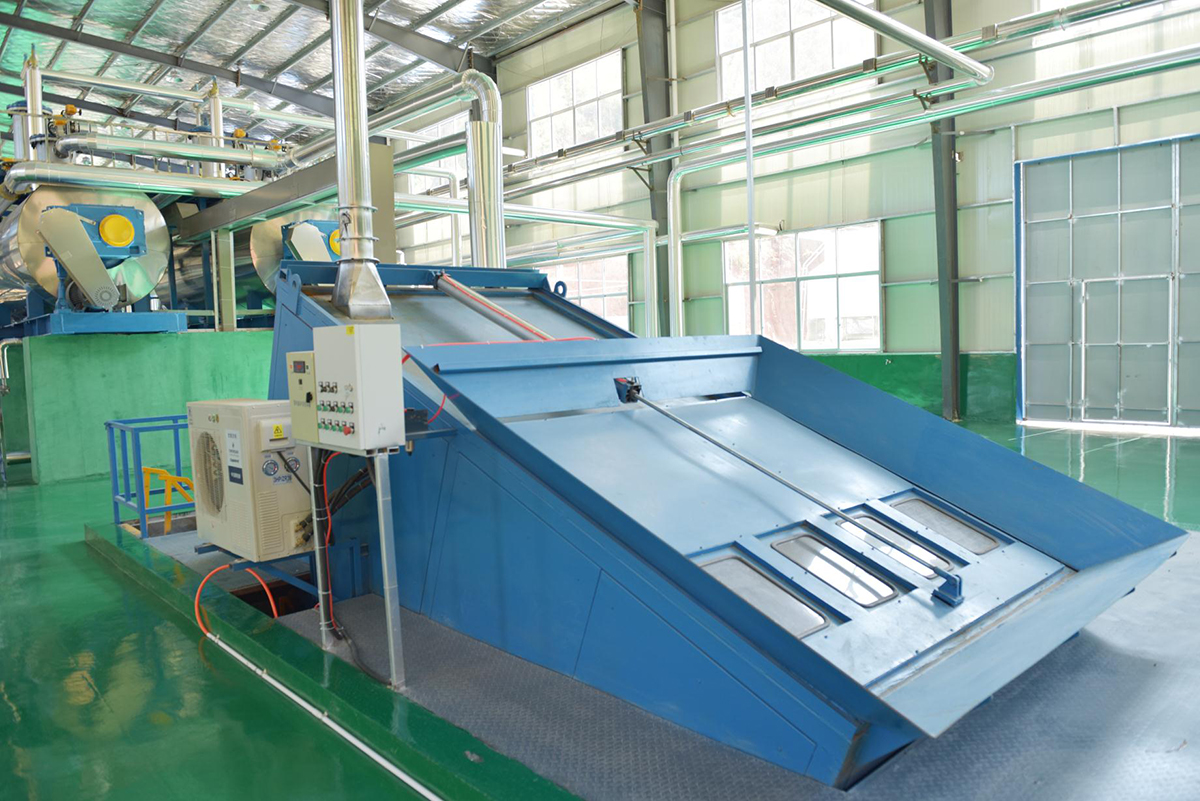

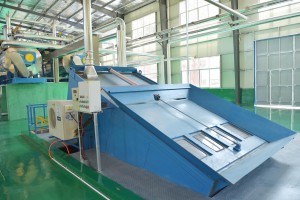

Poultry Waste Meat Meal Rendering Plant Feed Processing Machine is suitable for poultry,poultry waste,pig,cow,sheep,fish,feather,bone,blood,

all animal waste.High efficiency,all the machine can be equipped by customers requirement ,a complete production line or a simple one just depend on all customers choice.

Finally product will be meal and oil,the meal can be used for poultry feed,the oil will be used for industrial oil.

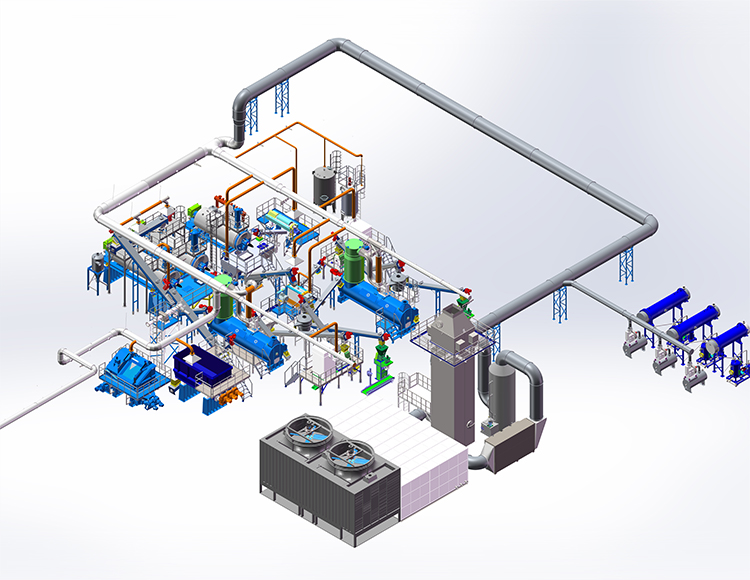

Raw Material Workflow

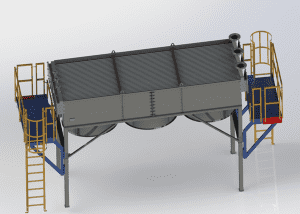

Pre-breaker System–Screw–Cook and Dry–Buffer–Press–Cooling–Mill–Automatic Packing

Waste Process Workflow

Waste Air Cooling–Spray and Washing–Flitter–High-energy Photon Oxidation–Discharge after reaching standard.