High quality High Quality High Production Bird Feather Meal Processing Machine Rendering Plant Fish Feed Processing Line

Short Description:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of High quality High Quality High Production Bird Feather Meal Processing Machine Rendering Plant Fish Feed Processing Line, How about to start your good organization with our corporation? W...

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of High quality High Quality High Production Bird Feather Meal Processing Machine Rendering Plant Fish Feed Processing Line, How about to start your good organization with our corporation? We are all set, properly trained and fulfilled with pride. Let’s start our new business enterprise with new wave.

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of China Fish Feed Extruder and Fish Food Machine, Welcome to visit our company, factory and our showroom where displays various hair items that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to offer you the best service. Make sure you contact us if you want more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

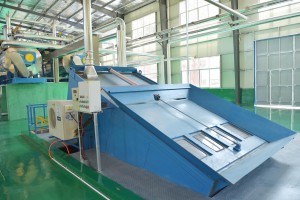

The mill is used to reduce the particle size of the greaves after fat extraction.The reduction in size required at this stage depends on whether the meal is used directly in compound feeds or it will be passed through a further stage of size reduction.

Features

1.Unique crushing chamber that could improve the grinding efficiency

2.Special rotor design program,and the hammer sieve gap,which can meet different granularity