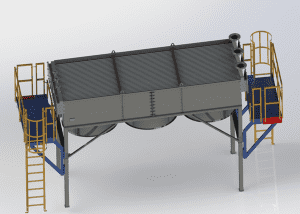

Factory supplied Horizontal Double Shaft Feed Mixer Poultry Feed Grinder and Mixer Machine

Short Description:

As a way to finest meet up with client’s wants, all of our operations are strictly performed in line with our motto “High Quality, Aggressive Price, Fast Service” for Factory supplied Horizontal Double Shaft Feed Mixer Poultry Feed Grinder and Mixer Machine, While using the improvement of society and economy, our enterprise will hold a tenet of “Focus on trust, high quality the first”, moreover, we count on to make a glorious long run with each and every customer...

As a way to finest meet up with client’s wants, all of our operations are strictly performed in line with our motto “High Quality, Aggressive Price, Fast Service” for Factory supplied Horizontal Double Shaft Feed Mixer Poultry Feed Grinder and Mixer Machine, While using the improvement of society and economy, our enterprise will hold a tenet of “Focus on trust, high quality the first”, moreover, we count on to make a glorious long run with each and every customer.

As a way to finest meet up with client’s wants, all of our operations are strictly performed in line with our motto “High Quality, Aggressive Price, Fast Service” for China Feed Mixer and Poultry Feed Grinder and Mixer, We always insist on the management tenet of “Quality is first, Technology is basis, Honesty and Innovation”.We are able to develop new solutions continuously to a higher level to satisfy different needs of customers.

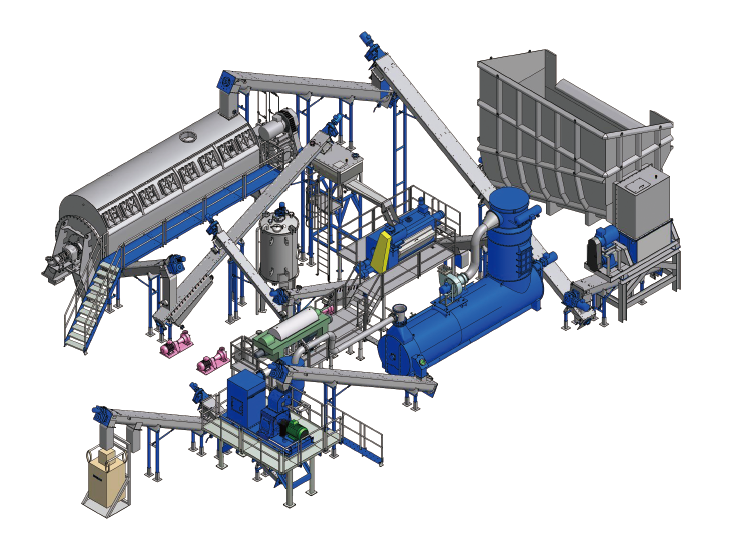

Poultry Waste Meat Meal Rendering Plant Feed Processing Machine is suitable for poultry,poultry waste,pig,cow,sheep,fish,feather,bone,blood,all animal waste.High efficiency,all the machine can be equipped by customers requirement,a complete production line or a simple one just depend on all customers choice.

Finally product will be meal and oil,the meal can be used for poultry feed,the oil will be used for industrial oil.

Raw Material Workflow

Pre-breaker System–Screw–Cook and Dry–Buffer–Press–Cooling–Mill–Automatic Packing

Waste Process Workflow

Waste Air Cooling–Spray and Washing–Flitter–High-energy Photon Oxidation–Discharge after reaching standard