factory low price Diesel Engine Floating Pelleting for Fish Meal Making Machine Feed

Short Description:

We emphasize advancement and introduce new products and solutions into the market each year for factory low price Diesel Engine Floating Pelleting for Fish Meal Making Machine Feed, Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We emphasize advancement and introduce new products and solutions into the market each year for China Fish Meal Making Machine Feed and Agricultural Waste Pellet Making Machine, Now we have constru...

We emphasize advancement and introduce new products and solutions into the market each year for factory low price Diesel Engine Floating Pelleting for Fish Meal Making Machine Feed, Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

We emphasize advancement and introduce new products and solutions into the market each year for China Fish Meal Making Machine Feed and Agricultural Waste Pellet Making Machine, Now we have constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and professional after-sale service supplied by our consultant group has happy our buyers. Comprehensive Info and parameters from the merchandise will probably be sent for you for any extensive acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

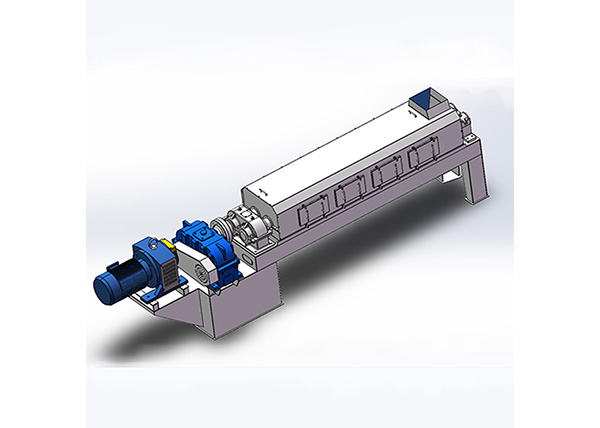

For pressing liquids from cooked fish or meat in a wet rendering process. The twin screw press ensures eficient mechanical dewatering and reduction of the oilfat content, which improves processing and increases the energy saving potential. The twin screw press attains a condition of high compression resulting ina low moisture and oilfat content in the press cake.

The press consists of two interlocking screws enclosed by a strainer shell and surrounded by a cover. The flights’ geometry can be cylindrical or biconical depending on the performance required and the type of material being processed. The screws rotate in opposite directions, preventing the material from rotating with the screws.

The strainer cage consists of perforated stainless steel plates surrounded by mild steel supporting plates, which are supported by heavy steel bridges.The strainer plate holes vary in size of the press from inlet to the outlet from 5 to 1. The twin screwpress can be dlivered as a conical or a cyindrica press One of the advantages of the conical type is that the flights of one screwreaches almostinto the core of the other screw.The result is minimum slip in the press and a more uniform press cake.

Twin-screw presses are often used to extract liquid from cooked fish or meat as part of low-temperature wet rendering processes.

They are also ideal as the first stage in mechanical dewatering processes, before the material enters a centrifugal decanter centrifuge.

They can also be used in high-capacity feather plants.

| Type | Capacity (t/h) |

Dimension(mm) | Weight (mt) |

Power (kW) |

||

| Length (L) | Width (W) | Height (H) | ||||

| TP 24 | 2.5 | 4400 | 1250 | 1030 | 3 | 7.5-11 |

| TP 35 | 5 | 5460 | 1800 | 1300 | 7 | 11-18.5 |

| MS 41 | 13 | 4600 | 2000 | 1500 | 9.5 | 22-37 |

| MS 49 | 18 | 5700 | 2400 | 1950 | 15.5 | 30-55 |

| MS 56 | 25 | 6700 | 2500 | 1870 | 23 | 45-75 |

| MS 64 | 40 | 7400 | 2800 | 2100 | 31 | 90-110 |

| RS64 | 50 | 8350 | 2800 | 2100 | 34 | 110-132 |

| XS88F | 60 | 8400 | 2850 | 2165 | 46 | 95-132 |